Safety

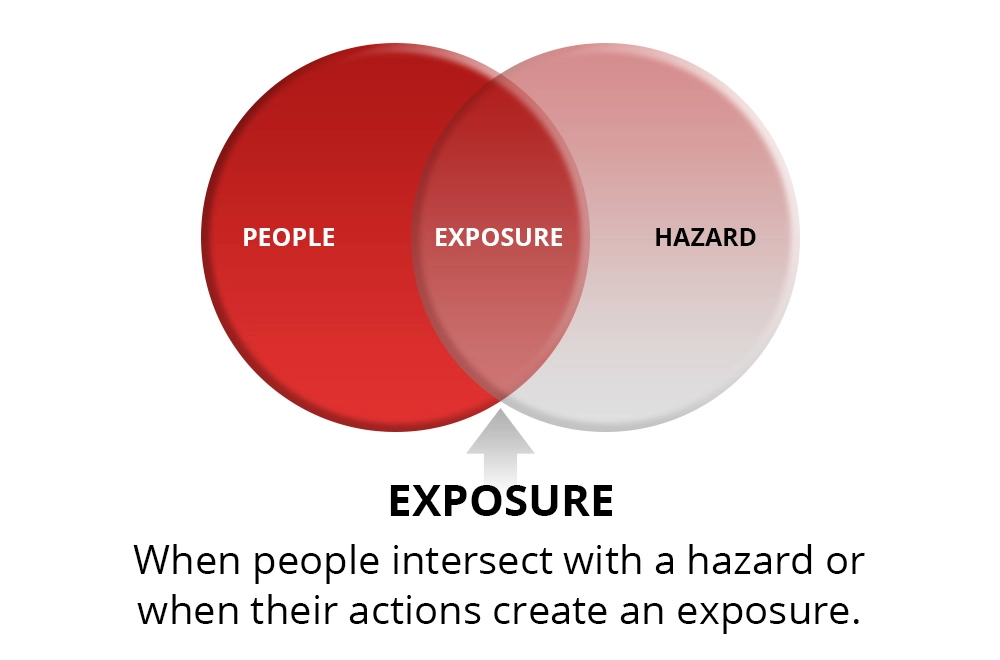

Safety is controlling exposure to self and others "everyday....Everyone stays alive & well"!

Jump To:

Our Safety Philosophy

At RHC we define safety as controlling exposure to self and others.

RHC is committed to meeting a set of high safety standards throughout the process of each of the construction services we perform. By following our safety philosophy, we take every safety measure necessary to make sure every day everyone goes home alive and well while completing every task the right way every time.

The RHC Safety Philosophy

Everyone Goes Home Alive and Well Every Day!

- All injuries, incidents and occupational illnesses are preventable.

- Preventing incidents and injuries to ensure all employees go home safe every day is our most important business objective.

- Safety is line management’s responsibility, including front-line supervisors.

- Working safely is a condition of employment.

- Employees have the obligation to stop unsafe operations

Our team has worked tirelessly to develop our own brand of safety. We’ve developed sets of quality safety measures and services for both internal and external use, making our approach to safety different from any other construction company.

RHC's Internal Safety Measures

- RHC requires comprehensive safety training for all our employees and contractors.

- We dispatch an experienced and highly-qualified team of dedicated safety professionals to serve on every job site.

- A highly-trained Behavior Based Safety Management (BBSM) team.

- An industry-leading incident investigation process.

- A custom-built safety database and incident reporting system.

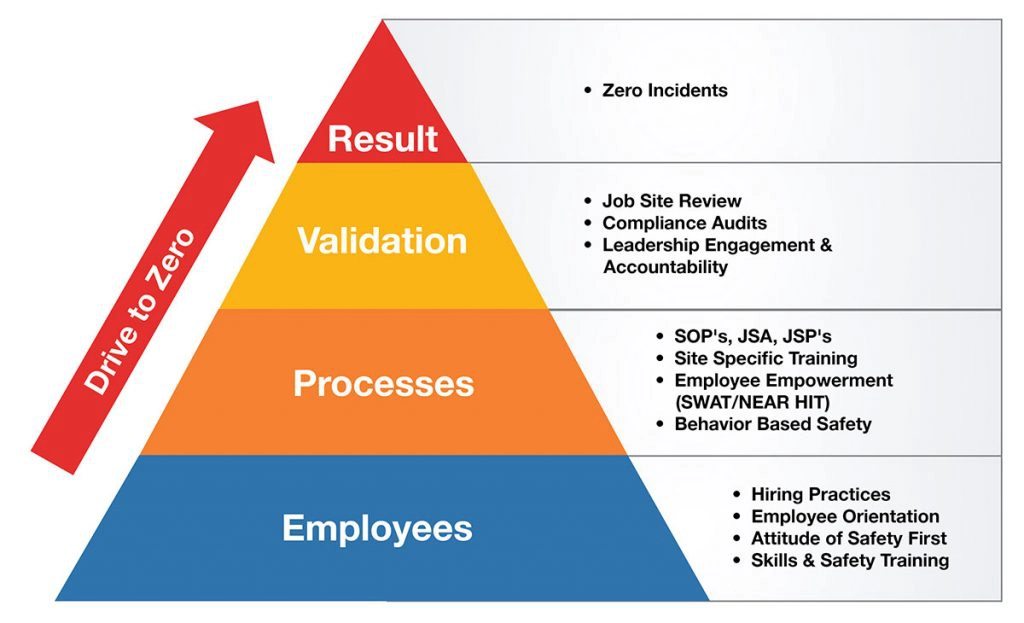

How We Do It

Preparation & Planning

- Standard Operating Procedures (SOP’s) for most activities

- Job Safety Plans (JSP’s) for all High Hazard Activities

- Job Safety Analysis’ (JSA’s) for all field processes every day

Employee Engagement

- Behavior-Based Safety Management (BBSM) since 1997 & licensed with BST

- Stop Work Authority Taken (SWAT) process with which all employees are empowered and expected to participate in

Advanced Information Systems

- Comprehensive Reporting an Information Management System. This system gives us the data to perform advanced predictive analytics to spot breakdowns in our system or potential high probability incidents before they happen. In this system we track all:

- Incidents

- Near Hits

- SWAT cards

- Corrective Actions

- Reports

- Scorecards

Leadership Engagement

- Safety Advisors coach and mentor RHC operational supervision

- Managers perform advanced safety audits with customers

- Executive engagement at safety meeting and in the field at all locations

Compliance Assurance System

- This is a closed loop system which allows us to track our audit results and corrective actions to ensure that corrective actions are being implemented and followed up on in a timely manner. This system tracks all:

- Job Safety Reviews

- Audits

- Corrective Actions

- Reports

- Scorecards

Project Safety Awards and Recognitions

Don’t just take our word for it, RHC has received the following safety awards:

ABC National Safety Pinnacle Award

To achieve ABC’s highest Safety Excellence Award, a company must have previously won the National Safety Excellence Award and be judged by a National Board of Directors as a “Truly World Class” safety organization.

ABC STEP Platinum Award

To achieve ABC STEP Platinum level, a company must have a total recordable incident rate at least 25 percent below specific industry averages for the NAICS Code and maintain an EMR of 0.80 to receive this award.

ABC STEP Diamond Award

To achieve ABC’s STEP Diamond level, a company must have a total recordable incident rate at least 50 percent below specific industry averages for their NAICS Code and maintain an EMR of 0.70.

ABC National Safety Excellence Award

Out of 30,000+ ABC member firms across the country, fewer than 800 are eligible to apply – that’s less than 3 percent of the entire ABC membership!